CNS Technologies - Import and export expertise with Technology

Introduce

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

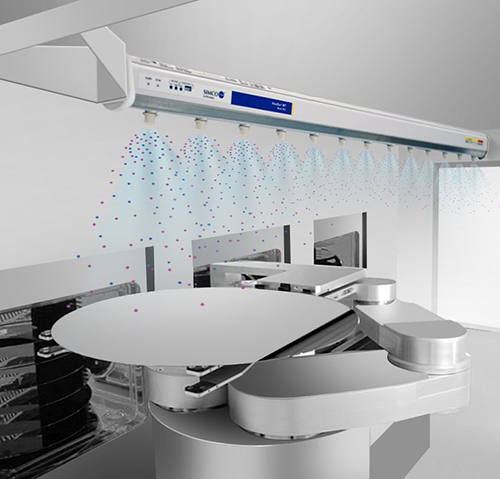

Modulated Pulse Technology with Wide Adjustability & ISO 14644-12 Ionization

Simco-Ion's AeroBar 5635 Modulated Pulse ionizing bar is specifically designed to eliminate static charge in semiconductors and other ultra-clean manufacturing processes where fast discharge time, low swing voltages, and precision balance are required. The Model 5635 utilizes MP technology, combining a high-frequency sine wave with modulated pulses (MP) for high ion output and delivery. This breakthrough technology enables AeroBar mounting within 150 mm of the wafer. MP technology, combined with ultra-clean silicon emitter points and precision adjustment, provides ISO 14644-12 ionization (0.01 µm particles or nanoparticles) and ISO 14644 Class 1 (0.1 µm particles) cleanliness, critical for smaller technology nodes.

- Extended ISO Class 1 (10 nm) particles cleanliness

- Modulated pulse technology

- Excellent lateral uniformity

- Low field voltages

- Air-assist capability

- Optional software with an easy-to-use interface with wide adjustability

- Alarm output signal

TARGET MARKETS

- Front-End Semiconductor Manufacturing

TARGET APPLICATIONS

AeroBar 5635 is specifically designed for semiconductor wafer processing and the stringent cleanliness and performance requirements at smaller geometries. It provides ISO 14644-12 ionization (0.01 µm particles or nanoparticles) and ISO 14644 Class 1 (0.1 µm particles) cleanliness.

Loading ...

Loading ...